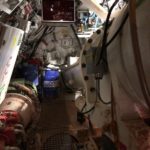

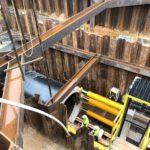

Work is underway on Houston’s Northeast Transmission Line, a 108-in. diameter pipeline intended to move up to 365 million gallons per day of treated drinking water 16.5 miles across the city’s urban landscape. This project required the design of a pipe brake system for a tunnel launch pit. The system was designed to restrain the hydrostatic forces on the EPB TBM cutting face. Stiver Engineering provided plans for the shoring design, as well as the concrete tunnel eye where the pipe brake system would be anchored. Anchor points were designed for both the tunnel eye seal and the steel casing pipe. We also provide a design of a concrete thrust block.

Get Started Today!

Stiver Engineering Commitment

“We are driven by a passion for getting the job done. Every challenge presents an opportunity for innovation, and we embrace those challenges by engineering unique solutions that ensure our clients’ success.”

– JOHN STIVER

"*" indicates required fields

Or Call Us At

[713] 526-3478